AMS Alliance NexaFlo™ Segmented Flow Analyser

Next Generation Segmented Flow Analyser Technology

The NexaFlo™ Series symbolizes KPM's cutting-edge approach to segmented flow analysis, drawing upon three decades of analytical chemistry expertise under our AMS Alliance umbrella. This innovative solution provides a comprehensive method for analysing a diverse range of samples, including sea water, drinking water, wastewater, environmental samples, soil, food, beverages, tobacco, and various other materials. Through full automation of the sample preparation process, the NexaFlo™ Series enables remote control of startup and shutdown procedures via computer, revolutionizing laboratory workflows by streamlining labour-intensive and intricate sample preparation tasks.

Ideal for laboratories seeking superior detection capabilities in Segmented Flow Analysis, particularly in marine and environmental testing for identifying substances like ammonia in water, the NexaFlo™ Series streamlines operations with automated processes, efficient use of reagents, and waste reduction. With support for up to 14 consoles, this series offers flexibility to meet the demands of complex laboratory requirements, optimizing workflow, ensuring precision and safety, and modernizing operations to enhance safety, efficiency, and accuracy in various research fields.

Features

Enhanced Modularity: Create sophisticated instrument configurations with up to 14 channels, various flow cells, and both micro and macro flow options.

Optimal Performance: Increase efficiency with a dedicated analytical console supporting high throughput of up to 120 samples per hour, complete with an auto-sampler. Streamline routine and complex chemistry tasks through full automation.

Cutting-Edge Software: Specifically designed for Segmented Flow Analysis, this intuitive software oversees all parameters for each channel and accessory. Compliant with EPA / ISO methods for diverse matrices.

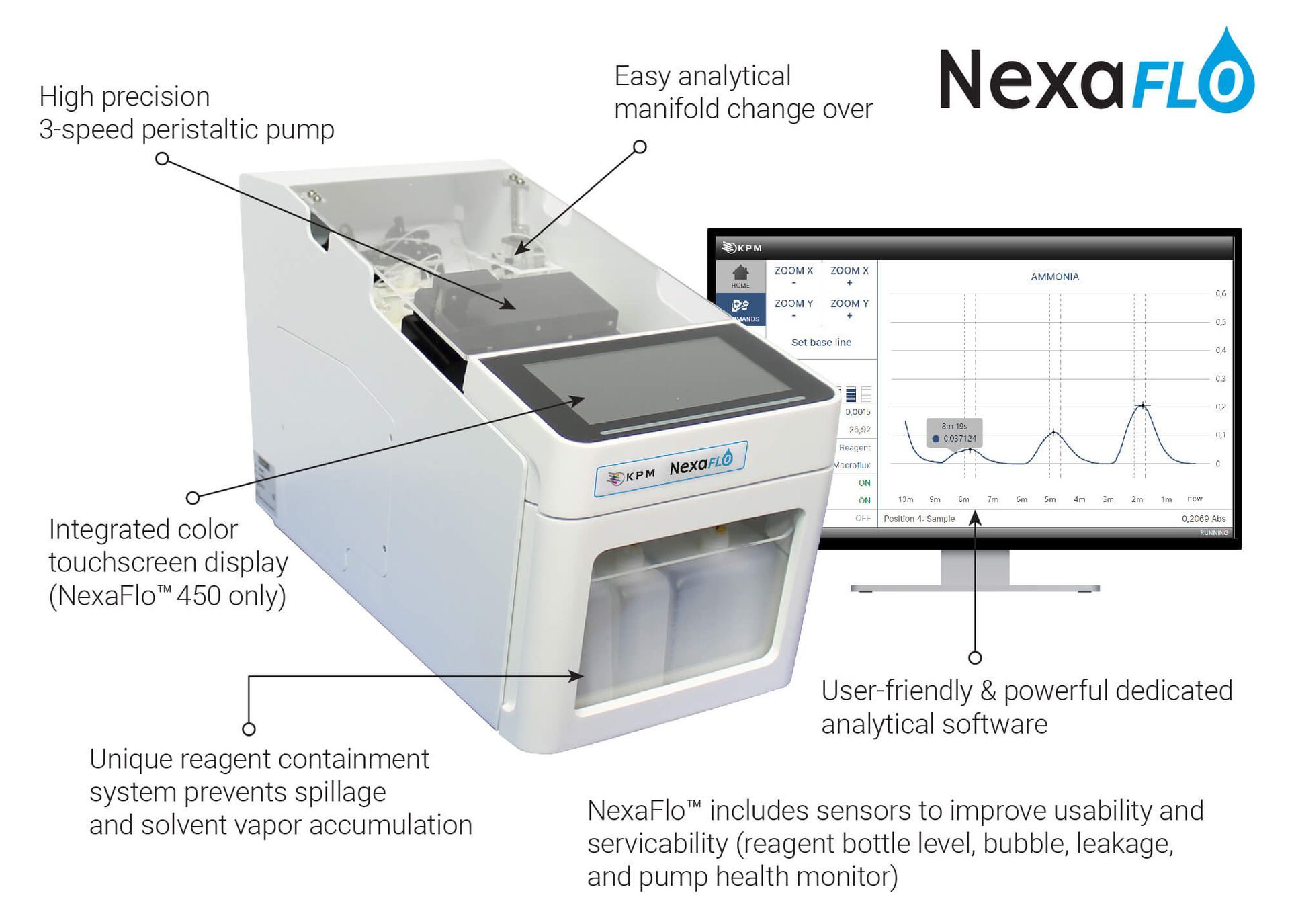

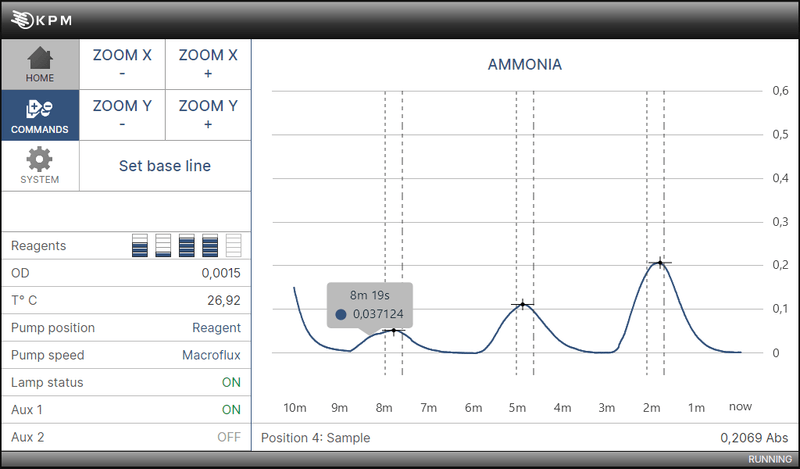

User-Friendly Functionality and Easy Maintenance: Includes diagnostic features, LED health indicators, and a manifold leak detector. Features an integrated colour touchscreen display for real-time monitoring and adjustment of methods and chemistries (exclusively with the NexaFlo™ 450). Facilitates access to components for simplified maintenance.

Adherence to Standardised Methods: Ensuring compliance with reference methods.

Benefits

Enhanced Safety: Innovative reagent containment ensures minimal exposure to solvent vapours and spills, promoting a cleaner workspace.

Enhanced User-Friendliness: Tailored console design and extensive accessory options meet various testing requirements. The integrated color touchscreen display enables real-time monitoring and adjustment of methods and chemistries (compatible with NexaFlo™ 450).

Streamlined Maintenance: Clear LED status indicators and improved parts accessibility simplify upkeep tasks.

Scalability and Efficiency: The modular structure facilitates seamless adaptation and expansion of testing capabilities in labs.

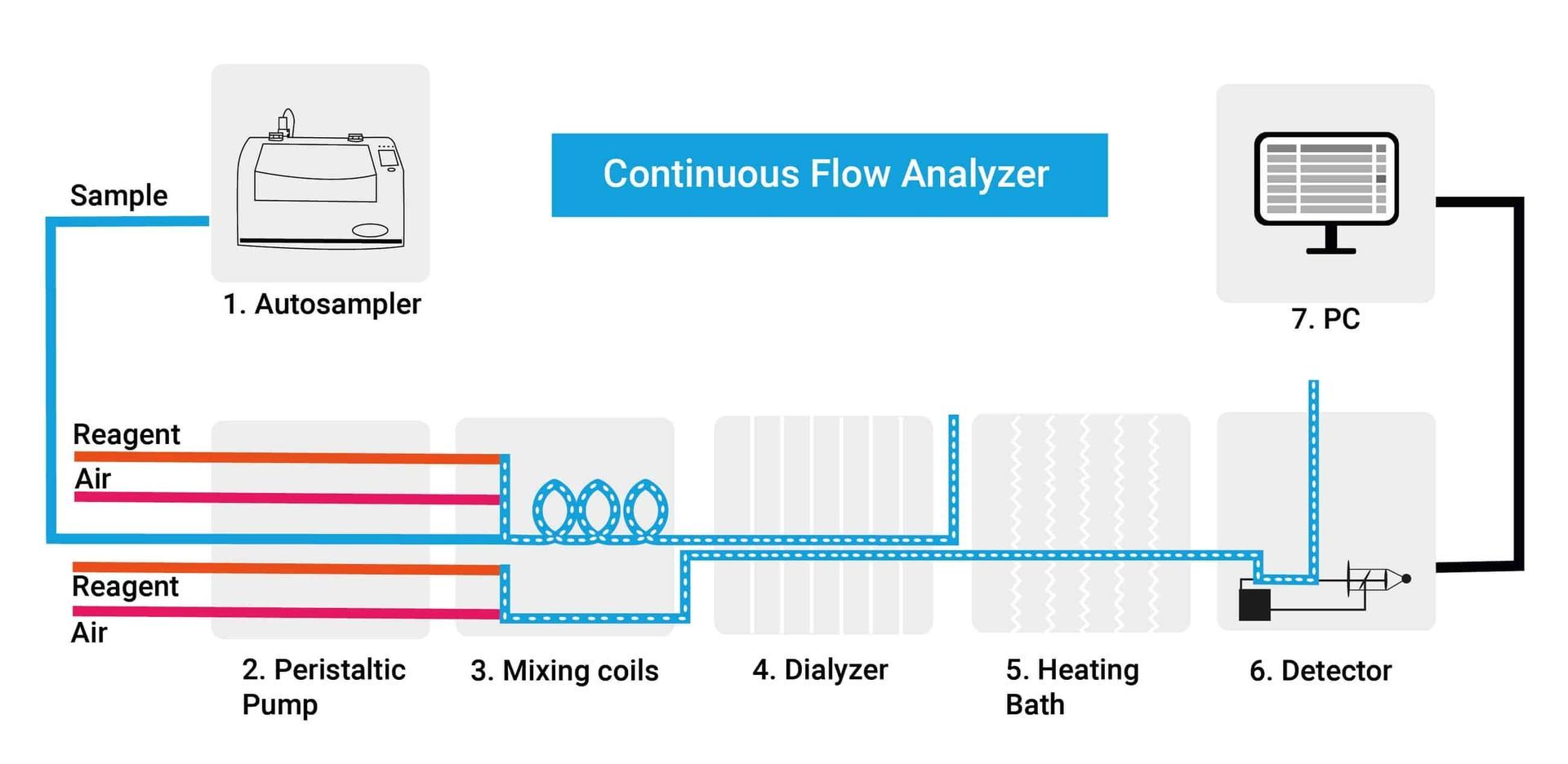

How it Works

The NexaFlo™ is a standout premier Segmented Flow Analyser (SFA), falling within the realm of Continuous Flow Analysis (CFA) techniques. SFA's unique air bubble segmentation method, a component of CFA, merges the benefits of continuous flow with heightened accuracy and minimized cross-contamination. This one-of-a-kind approach empowers the NexaFlo™ to proficiently conduct a diverse range of analytical procedures.

Tailored to accommodate both micro-bore and macro-bore SFA techniques, the NexaFlo™ enables the seamless execution of intricate analyses, including colorimetric tests, in-line distillations, and digestions. With integrated support for an autosampler, managing sample intake is amplified, complemented by custom sample preparation systems designed for the specific analysis at hand. The NexaFlo™ software offers extensive control and operation capabilities, further bolstered by the optional Auto Module.

By leveraging automation, the NexaFlo™ excels at tackling complex sample preparation and operational activities. From dialysis and distillation to UV digestion, injection, dilution, mixing, incubation, and liquid/liquid extraction — each technique is executed with unmatched efficiency. All processes, including system initialization and shutdown, standard solution preparation, sample concentration adjustments, and automated cleaning protocols, are fully mechanized, ensuring superior throughput and precision in every analysis.

System Components

Each NexaFlo™ integrates a high-precision 3-speed peristaltic pump (medium, fast for startup and washout, and slow for low reagent consumption), an analytical manifold, a unique reagent containment drawer, and a UV-Vis Colorimeter detector (Flame Photometer and Fluorimeter available are options). Additionally, the NexaFlo™ 450 features an integrated colour touchscreen display, whereas for other NexaFlo™ models, the software displays through an external PC.

Software

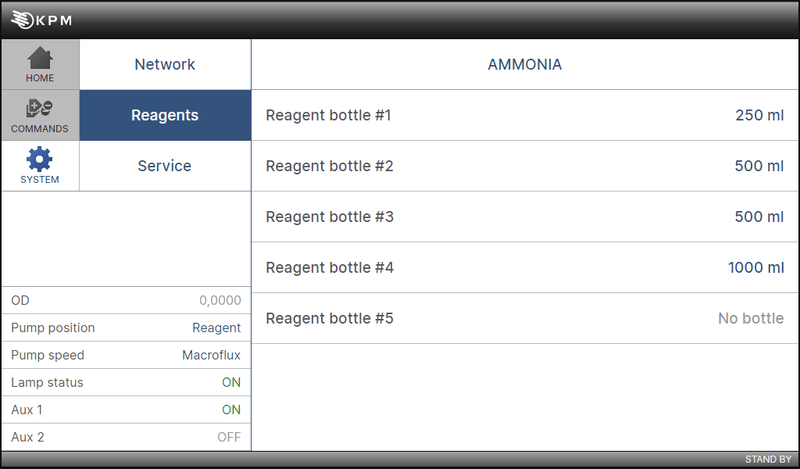

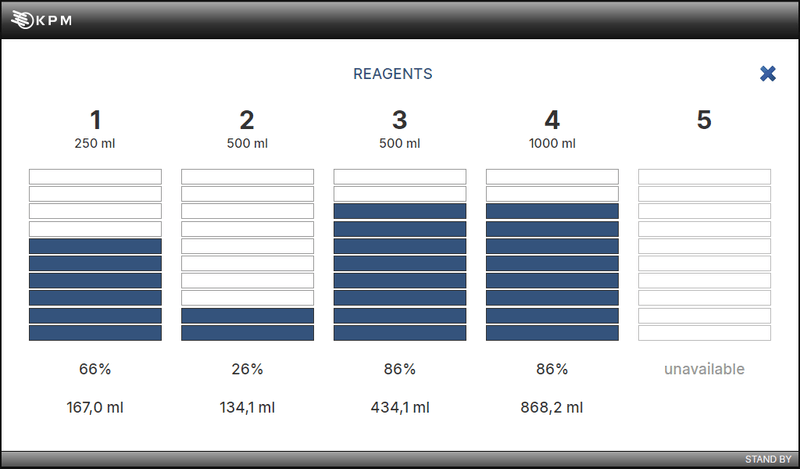

The NexaFlo™ analytical software is dedicated to Segmented Flow Analysis, a subsegment of Continuous Flow Analysis (CFA) technology. It prepares calibration standards, runs samples and quality controls, dilutes any out-of-range samples, prints reports and QC charts, exports data to LIMS, washes out the manifold and manages shutdown operations.

The software is user-friendly, efficient, and powerful, designed to simplify day-to-day operations. It runs the analysis of all parameters on each channel (up to 14 channels) and drives auto-samplers and accessories for automatic sample preparation. A simplified version of the NexaFlo™ software is run on NexaFlo™ 450 with a colour touchscreen display for easier diagnostics, maintenance, device setup, significantly improving the user experience.

During analysis, the software monitors all performance details (heating bath temperature, voltages, detector outputs) and alerts the user of any problems.

Resources

Servicing

Carekem are proud to offer a comprehensive selection of servicing options tailored specifically for the SmartChem®, FUTURA, Aquakem and Gallery analysers. Whether you require a repair, routine maintenance, training, or advice, Carekem's experienced team is equipped to meet your needs and ensure that your analysers perform at their best.