FUTURA Continuous Flow Analyser

Automatic Continuous Flow Wet Chemistry Analyser

The AMS Alliance FUTURA 3 Continuous Flow Analyser by KPM Analytics offers a comprehensive and dependable solution for analysing various parameters in sea water, drinking water, wastewater, environmental samples, soil, food, beverages, tobacco, and various other samples. The analysis process is fully automated, including inline sample preparation. By automating intricate and time-consuming manual sample preparation techniques, FUTURA 3 optimizes your laboratory workflows.

Additionally, FUTURA 3 features a selection of autosamplers tailored to your present and future laboratory requirements, along with an automated shutdown function that enables unattended and reliable operation, even for overnight testing. Its adaptable setup facilitates the simultaneous operation of up to 14 independent channels from a single workstation.

Features

- Complete Automation: enables programmable start-up and shutdown, standard solution preparation, pre- and post-dilution of off-scale samples, and automatic rinsing.

- Enhanced Modularity: accommodates integrated or combined instruments with up to 14 channels, multiple flow cells, and micro or macro flow capabilities.

- Optimal Performance: delivers high throughput, handling up to 120 samples per hour with an auto-sampler, while facilitating full automation of routine and complex chemistry tasks.

- Sophisticated Software: intuitive analytical software designed for user-friendliness, offering EPA/ISO methods for various matrices.

- Complies with recognized standards: ISO, EPA, AFNOR, APAHA, OIV, CORESTA.

Benefits

- Enhanced laboratory productivity is achieved through modularity and high throughput.

- The cutting-edge design and software tailored to CFA technology ensure the highest level of detection, comparable to reference methods.

- Streamlined processes and advanced automation minimize operator intervention time.

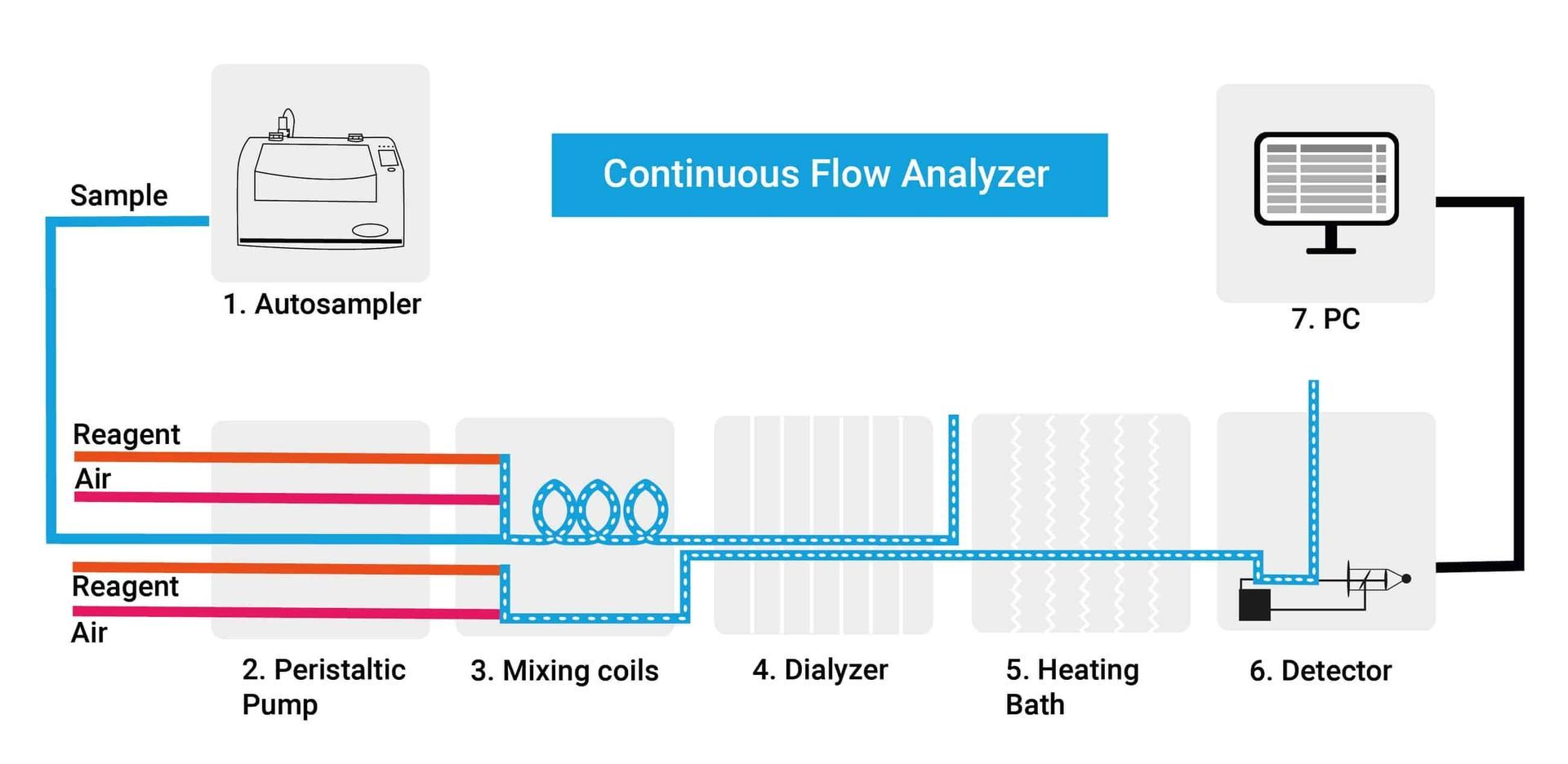

How it Works

The FUTURA 3 console enables a range of analytical methods through various Continuous Flow Analysis techniques, catering to everything from basic colorimetric assays to intricate in-line distillations and digestions. Users have the flexibility to choose from a comprehensive library of both micro-bore and macro-bore CFA methods.

For Continuous Flow Analysis to be carried out, the FUTURA 3 console needs to be paired with an autosampler that manages sample reception. Additionally, depending on the selected method, a set of sample preparation systems may also be required. All external components can be seamlessly controlled by the FUTURA software through the optional Auto Module.

The entire process, from sample preparation to operation, is fully automated, even for the most intricate chemical processes such as dialysis, distillation, UV digestion, injection, dilution, mixing, incubation, and liquid/liquid extraction - all conducted in-line and completely automated. Furthermore, the fully automated system encompasses programmable start-up and shut-down, standard solution preparation, pre- and post-dilution of out-of-range samples, and automatic rinsing.

System Components

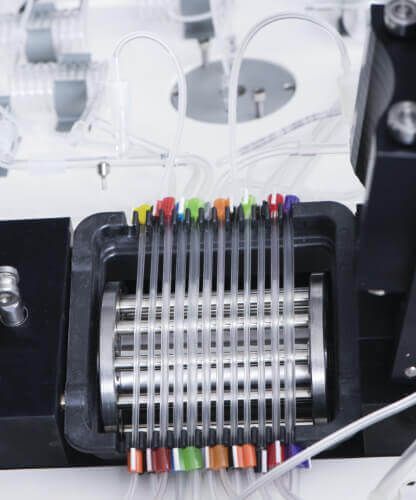

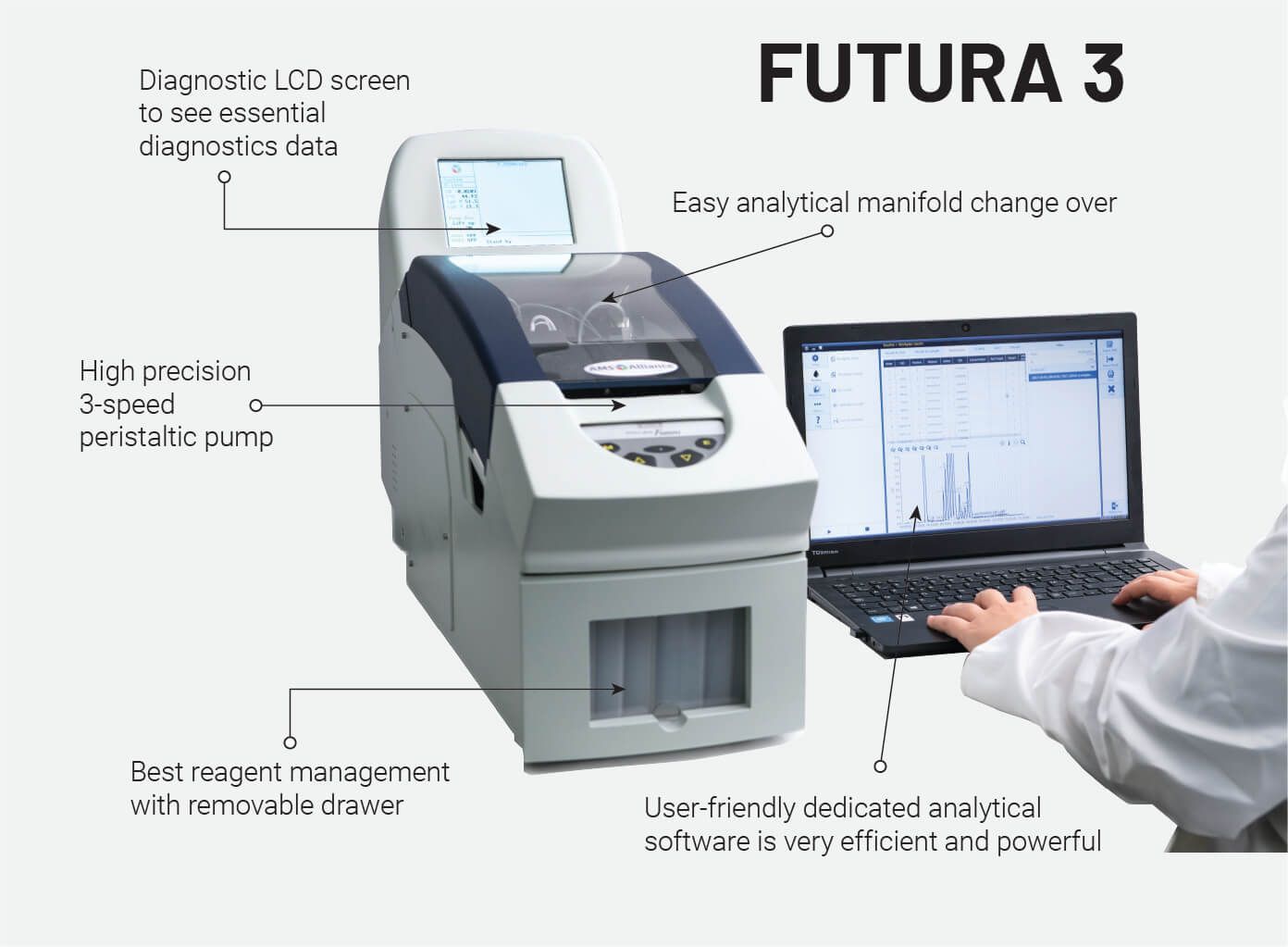

Every FUTURA 3 console comes equipped with a precise 3-speed peristaltic pump, offering medium, fast (for quick startup and washout), and slow (for efficient reagent consumption) settings. It also features a convenient reagent drawer, an analytical manifold, a heater, a detector, and an integrated display for showcasing crucial diagnostic information.

Software

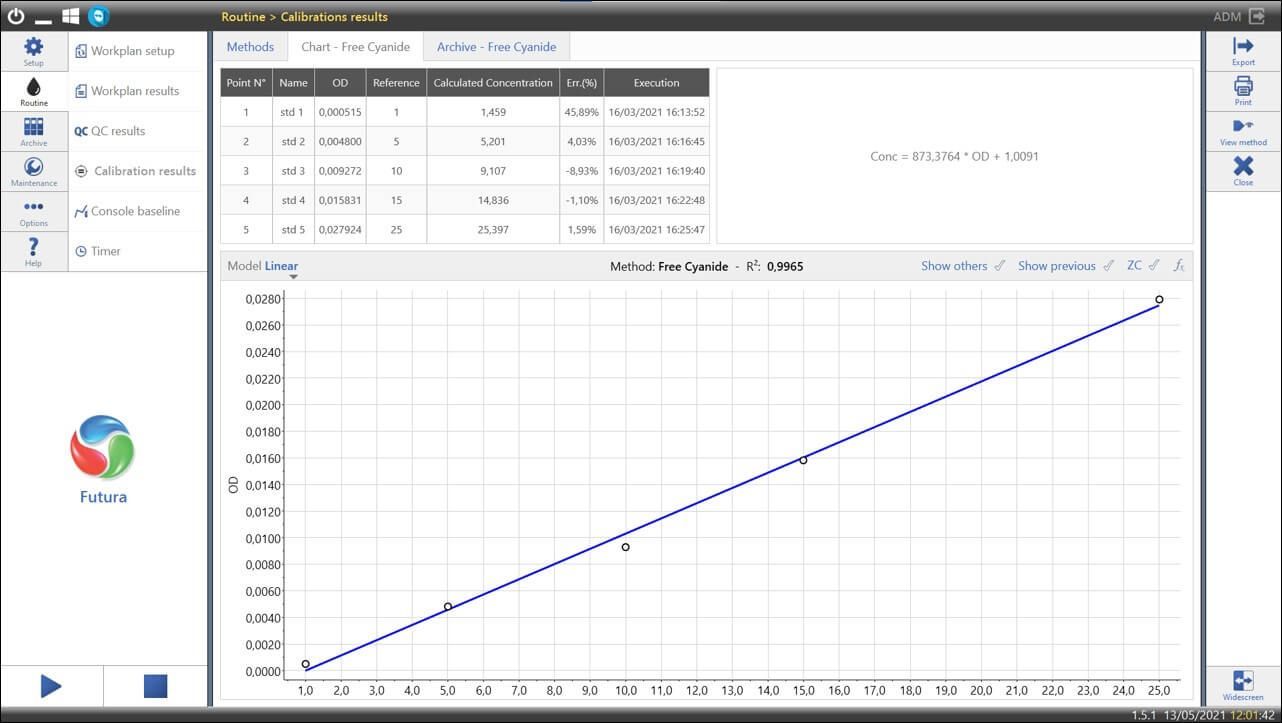

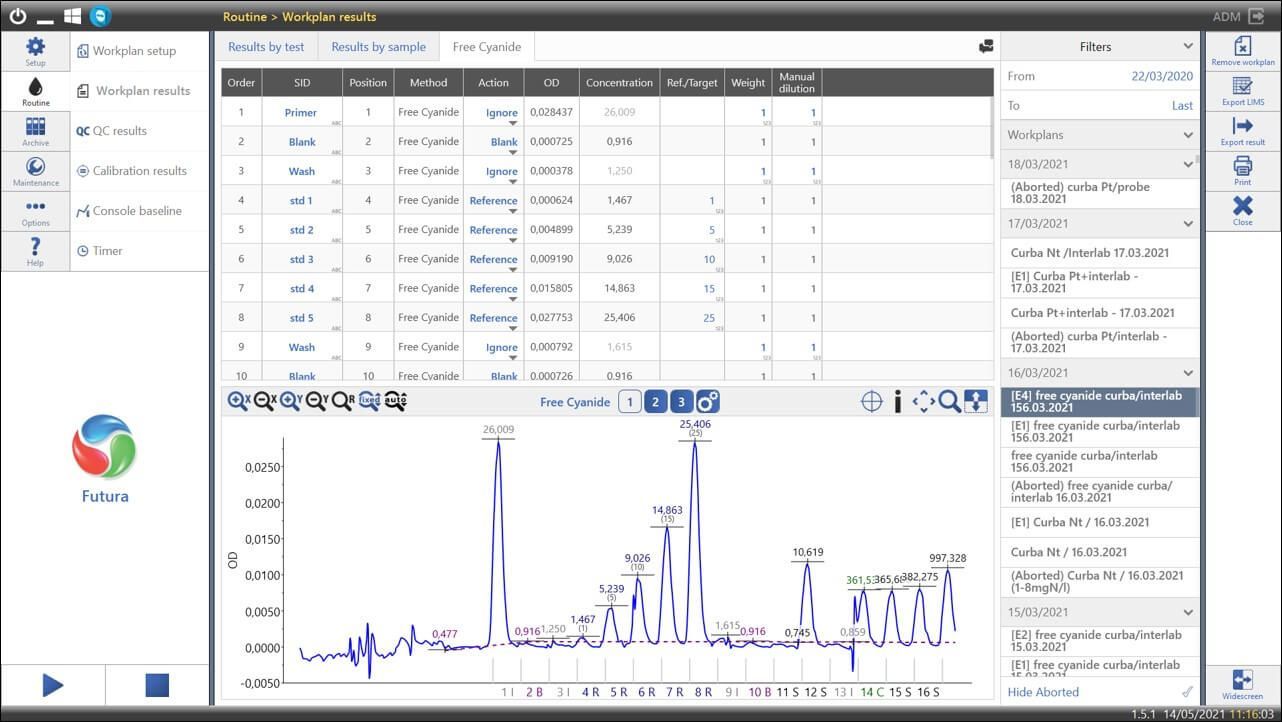

The FUTURA 3 analytical software is tailored for CFA technology, streamlining calibration standards preparation, sample runs, quality controls, off-scale sample dilutions, report printing, QC chart generation, data export to LIMS, manifold cleaning, and shutdown procedures.

User-friendly, efficient, and robust, this software simplifies daily operations by analysing all parameters across multiple channels (up to 14 channels), and managing auto-samplers and accessories for automated sample preparation.

Throughout the analysis process, the software monitors critical system parameters (heating bath temperature, voltages, detector outputs) and promptly notifies users of any issues.

Resources

Servicing

Carekem are proud to offer a comprehensive selection of servicing options tailored specifically for the SmartChem®, FUTURA, Aquakem and Gallery analysers. Whether you require a repair, routine maintenance, training, or advice, Carekem's experienced team is equipped to meet your needs and ensure that your analysers perform at their best.